Adelphi Automation

Automated Visual Inspection Systems

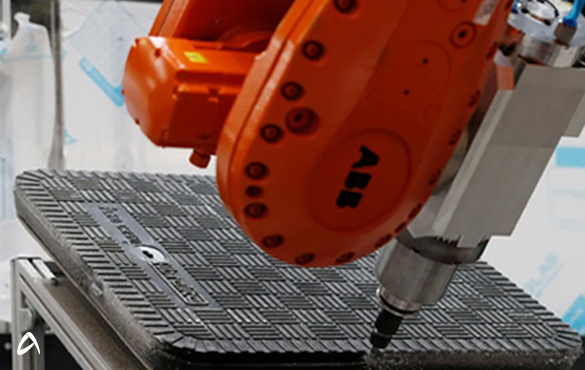

Improve the productivity of your manufacturing processes by automating the inspection of your products - whether that’s looking for deformities, contamination and other abnormalities, or measuring for quality assurance (QA).

Adelphi’s bespoke visual inspection systems are extremely accurate and designed with your operations in mind. We understand limiting factors such as obstructions and lighting conditions, that are often the result of the design process not accounting for an automated inspection system. This is why we are able to provide retrospective inspection systems, or design out the automated inspection errors inherently within your process.

Our engineers work around the requirements of your environment; we begin our services with site visits, so we can design a bespoke system which is suitable for you. With over thirty years of experience, our in-house team can design, manufacture and install a high performance and reliable automated visual inspection system.

Automated visual inspection systems carry out inspection tasks on products and parts that a human would otherwise do. This includes defect detection, contamination, vision test and measurement, and part verification amongst other quality assurance tests.

Supporting your next project

Get in touch with the team at Adelphi to discover how you can unlock the automation potential of your current systems.

Speak to the experts today...