Adelphi Automation

Robotic Welding

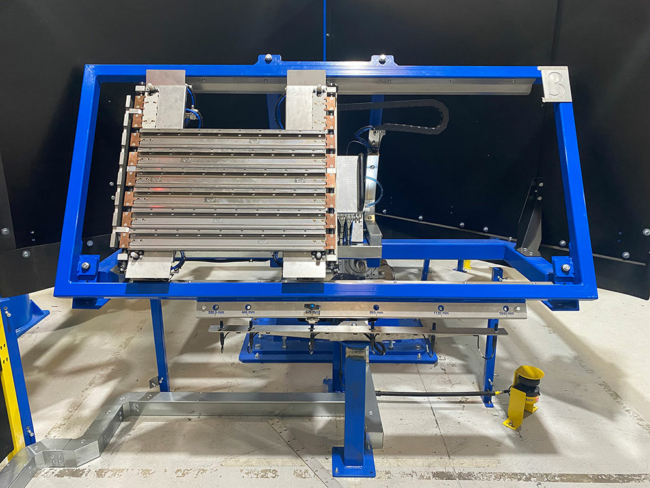

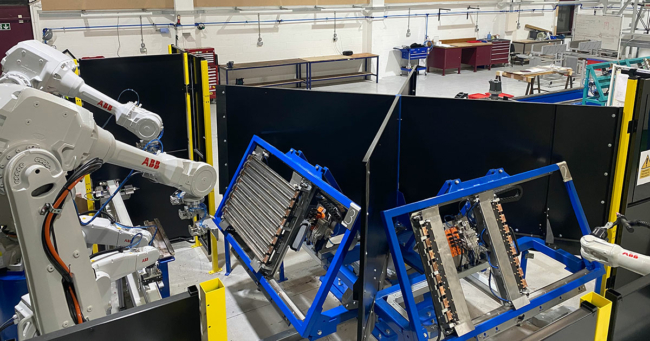

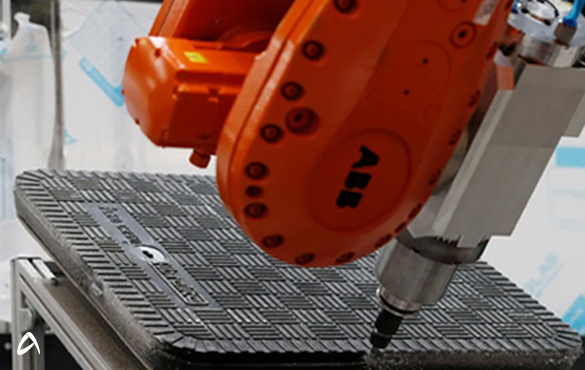

Adelphi’s expertise within the automation industry enables us to design and develop robotic welding solutions, specialising in MIG, TIG and FSW weld systems. We offer design, manufacture, and installation of complete robotic welding systems, for automation-assisted welds.

Working closely with our customers throughout a complete process, we help you decide the most suitable weld method for your operations and will specify the robot you require in consideration of this. We can also supply bespoke tools for your welding process to ensure you’re supplied with the equipment you need for your operations.

Our diligence during the design phases does not falter during manufacture and testing stages. All types of testing, including bend, tensile, and macro, are undertaken to ensure welds perform to the level required, whether this is a simple weld or highly intricate welds. This is supported by BBA reports which are further available upon request.

Our robotic welding systems are expertly designed to assist your processes with a highly efficient, accurate, and reliable solution, so that you’re supplied with the right equipment for your business.

Robotic welding is used for many types of welds within industries such as manufacturing and automotive, where a high volume of welding may be required.

Supporting your next project

Get in touch with the team at Adelphi to discover how you can unlock the automation potential of your current systems.

Speak to the experts today...