Adelphi Automation

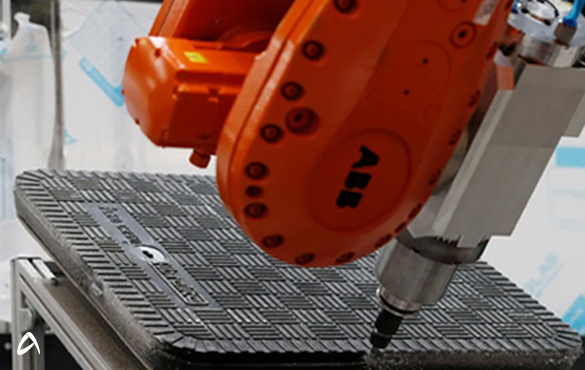

Robotic Palletising

Pick and stack boxes of different sizes and weights onto pallets quickly and easily with automated technology, ensuring your boxes are ready for transportation.

Adelphi’s robotics are designed to protect your products and minimise damage, with sensor and inspection technology available for integration into robotic systems in order to handle complex palletising operations, interchangeable box sizes, and delicate products with minimal interference.

Specialising in both the mechanical and electrical automation behind your robotics, we can make your palletising systems as bespoke and as advanced as required, with our expert team happy to take on a challenge.

With over 30 years of experience, the engineering team at Adelphi is well equipped to design the right automation system for you, providing a turnkey solution whether you’re looking to automate your complete production process with an assembly line, or automate your palletising operations only. Our bespoke approach to automation means we can work with you to design, manufacture, install and commission the perfect solution for your business.

Automated palletising is the automatic placement of boxed products onto a pallet, ready for transportation elsewhere; this is typically done at the end of an assembly line. The pick and placement process can be automated with the help of robots which are programmed to deal with the package, adjusting its actions where necessary to handle a selection of package dimensions.

Supporting your next project

Get in touch with the team at Adelphi to discover how you can unlock the automation potential of your current systems.

Speak to the experts today...