Adelphi Automation

Automatic Labelling System

Labelling is essential to preparing your products for processing or further transportation; however, it can often be a monotonous task which is best left up to automation.

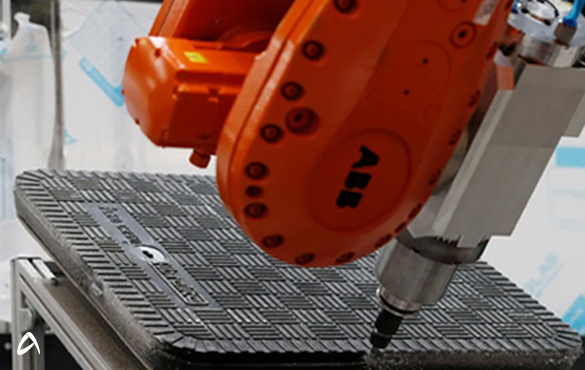

Adelphi’s bespoke automatic labelling systems are perfect for a range of high volume labelling requirements, offering solutions for all types of processes and operations. Our robotics can be integrated into your existing assembly and packaging lines to automate labelling processes, such as:

- Side labelling

- Wraparound labelling

- Top and bottom labelling

- Tamper evident labelling

At Adelphi, we can incorporate all project requirements, working with experience and expertise on robots and cobots for precise and fast automatic and semi-automatic industrial labelling processes. We can provide a full turnkey product for complete automatic assembly and palletising, or the mechanics you need to develop areas of your existing technologies.

This is true for all types of products, with our automation systems designed in mind of your products, such as interchanging product sizes and weights, or delicate products.

Our team of engineers is on hand to support you throughout the process of designing and integrating your bespoke system, so you benefit from a product which is truly fit for application.

Automatic labelling is the process of applying labels onto packages, ready for further transportation or distribution. Automatic labelling is carried out by automatic labelling systems, and used by a range of industries such as manufacturing, pharmaceutical, food and beverage, and distribution and parcel services.

Supporting your next project

Get in touch with the team at Adelphi to discover how you can unlock the automation potential of your current systems.

Speak to the experts today...