Adelphi Automation

Robotic Painting Systems

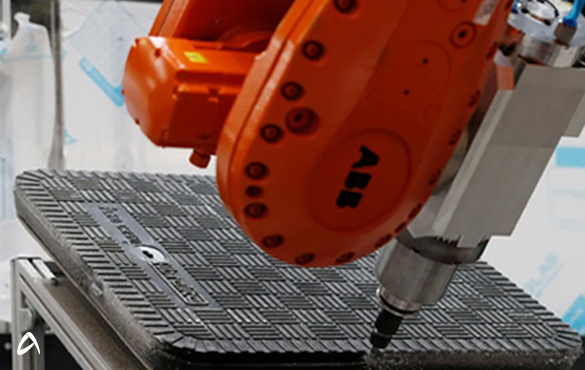

Adelphi’s custom robotic arms can be created for all types of painting application tasks, helping you to protect employees from potentially hazardous environments whilst improving the results you see.

Our automated painting systems can take on a variety of turnkey solutions, from spray guns to mixing systems, which can be integrated into either isolated cells or as part of the production process in conveyor lines. Our engineers design and build systems around your requirements, meaning the solutions we provide are always fit for purpose, and tested to the latest industry standards.

Whether dealing with small and simple parts or large, complex parts, our automated painting systems can deliver high quality results with even paint coats across a range of paints including solvents, waterborne and powder paints.

Easily extend the work envelope of your robot with additional axes or its handling capabilities with increased end of arm technologies - our engineers are on hand to support you throughout the design and integration process. Adelphi further provides ongoing maintenance support, valuing the long-lasting relationships we form with our clients.

There are several types of robotic painting systems, the design of which depends on the task it must perform and the piece it is coating. Sixth and seventh axis robots are most common, offering the greatest mobility to work on both interior and exterior surfaces of a complex workpiece with their robotic arm.

Supporting your next project

Get in touch with the team at Adelphi to discover how you can unlock the automation potential of your current systems.

Speak to the experts today...