Adelphi Automation

Robotic Component Trimming

The current manufacturing process includes layup and product moulding followed by manual finishing, such as flash removal and trimming, these are the areas that we were asked to consider when introducing robotic automation to help improve the process and product quality. Following the initial meeting, the design brief from our client was to conceive an automated solution to replace an existing manual finishing and trimming process undertaken by operators. The main consideration for our concept design was flexibility in operation and for the simple introduction of new product variants into the system.

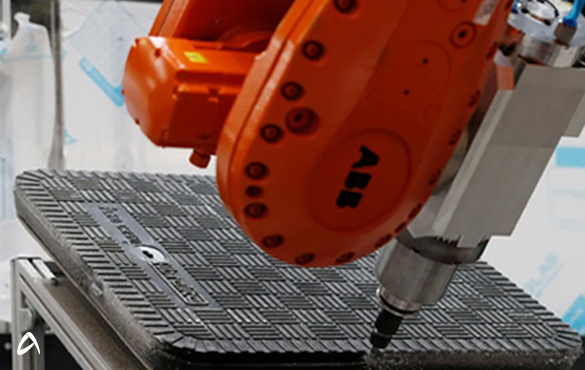

The system was designed to be installed into an existing extraction booth which has been retained and forms the enclosure for the robotic automation. This gave a major cost saving to the new process by using the existing infrastructure. Within the booth is a floor mounted six axis robot with foundry plus protection, this gives much greater levels of equipment protection, this is needed due to the dusty environment created by the process.

The robot carries an air cooled high speed electric spindle complete with an automatic pneumatic tool changer system to give the process of the desired flexibility. Within the new process the robot is able to change tooling in the spindle within the automatic sequence to give flexibility. In front of the robot is a floor mounted two station rotary table, designed to carry two vacuum fixtures. This functionality allows the component to load via the operator while the robot is processing the other fixture. The centre guarding on the table forms the enclosure and together with the floor scanner ensures the system is safe and meets all current legislation.

By introducing the automation our client has seen improved component quality and consistency, its personnel are no longer exposed to the harsh environment created by the original process.

Supporting your next project

Get in touch with the team at Adelphi to discover how you can unlock the automation potential of your current systems.

Speak to the experts today...